Developed by Hawkeye Industries in the USA, DURATEC and Aqua-Buff specialty products are used in the preparation and maintenance of composite plugs, patterns and molds in the automotive, architectural, leisure products, marine and transportation industries.

Ease of application, rapid coat build-up, low porosity, increased gloss and quick cure, are some of the features of the DURATEC range, saving time and labour, while ensuring a superior, smooth mold surface. Applications include Plugs and Patterns, In-Mold Priming, Mold Surfacing, Repair and Re-Surfacing and Preparation of Wood and MDF Surfaces.

Established in 1946, Cruise Craft in Brisbane specialised in building fibreglass boats for 54 years.

Justin Nichols, Director at Cruise Craft stated “Plug and mold making is a process which we have honed through those years of experience.

“We know that with a better Plug finish, it results in a better mold finish, which results in time savings with the ongoing manufacturing process.

“Up until recent years we had relied on a particular marine 2-pack poly-urethane paint system which yielded excellent surface finish and gloss retention to the mold. When that product became no longer available in Australia, we started trialling other brands’ poly-urethane systems which resulted in chemical reaction with the tooling gel-coat.

“This caused the plug and mold surface to print during the mold lamination process, prompting us to find a different system.”

They contacted Mick Bunker at ATL Composites for information about the Duratec system.

“Not only did he provide us with application guides and safety data sheets, he walked us through the specific products to best suit our application,” continued Justin.

“From there he followed us through the stages, answered our questions and instructed us on the best techniques that others have found using the Duratec system. This proved invaluable as a few of the surface finishing steps were vastly different to paint systems.

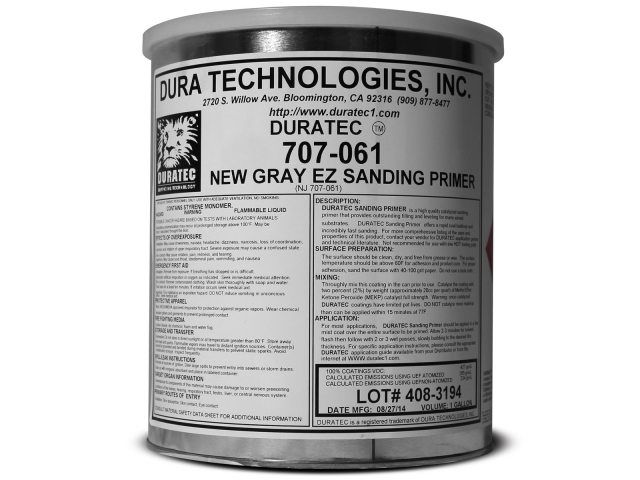

According to Justin, the combination of the 823 Clear Sealer and 707-061 Sanding Primer coats over the various materials used to shape the Plug substrate.

“Although the flash-off time of the primer was very fast, it enabled us to easily build up multiple thin coats to prevent trapping solvent. As a result, the cured surface was very dry and didn’t clog the sandpaper yet soft and easy to fair.

“Other paint systems we have used tended to be very finicky in terms of adjusting types and volumes of solvents and accelerators depending on normal fluctuating environmental conditions.

“With a fine margin for error of those systems, a dry but soft surface outcome seems like an oxymoron. The Duratec primer achieves that balance with tolerable working parameters.

In addition, the team at Cruise Craft was exceptionally happy with the ease of use and results of the 1902-045 Black VE Tooling Topcoat.

“A fast but controllable application then working through the necessary grades of dry sandpaper (an emphasis on dry sanding rather than wet, as advised by Mick), finishing with appropriate cuts of Aqua-buff 2000 Polish before releasing wax as per usual.”

Once the finished mold was released, they were satisfied with the perfect flat surface transfer between plug and mold.

“With both the Duratec system and Tooling gel-coat being Vinyl-ester based, there was no chemical reaction or post curing print back,” said Justin. “It is always a great relief when a brand-new mold is released from a plug and it is a greater relief when it happens from a new and unfamiliar product.

“We are very impressed with the Duratec products and can highly recommend it along with ATL Composites’ supply and technical support.”

Find out more about DURATEC applications and techniques here https://atlcomposites.com.au/product/82/Duratec-Application-Techniques