A revolutionary WA-made 3D printing platform that can build boats, civil formwork and industrial parts from recycled plastic has received a $385,000 boost from the Australian Government.

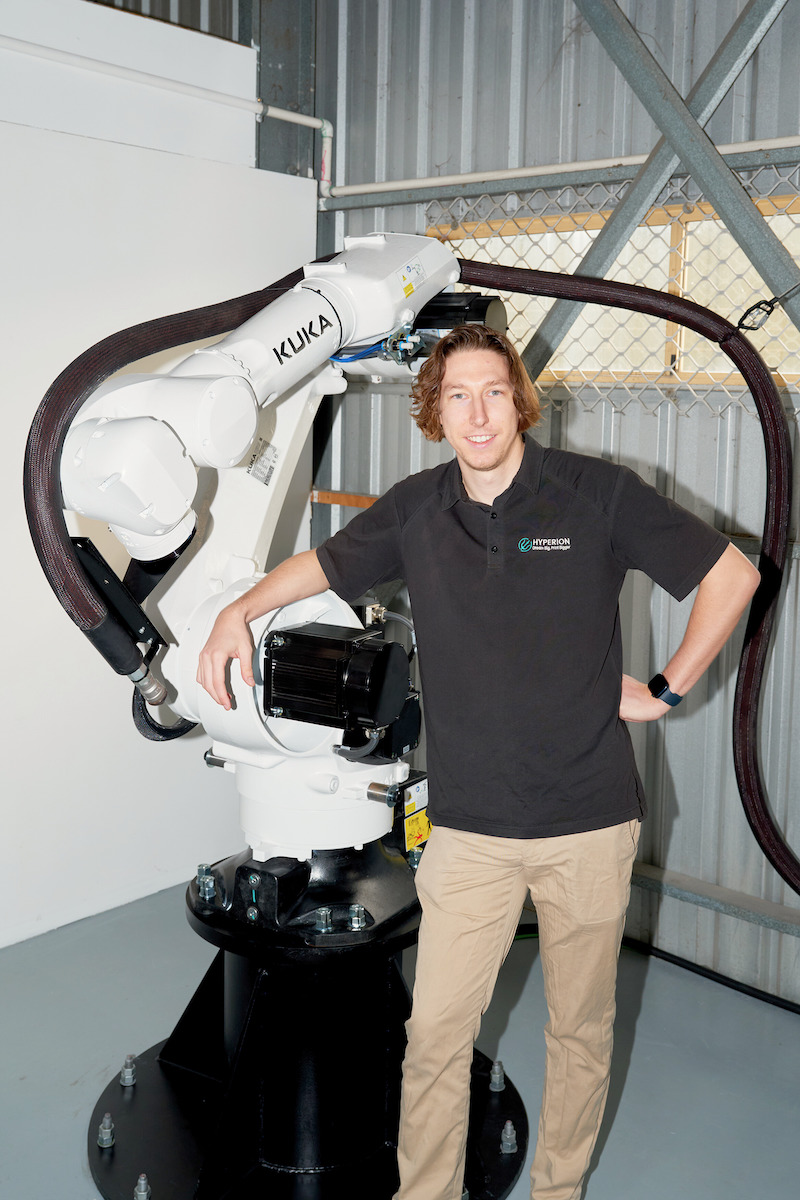

Hyperion Systems, founded by 27-year-old robotics engineer Josh Wigley, has secured a matched-funding grant through the Government’s Innovation Growth Program to commercialise its modular, large-format 3D printing platform.

Nicknamed the ‘Factory-in-a-Box’, the system is a self-contained, industrial-scale 3D printing unit that is transportable and can be immediately operated by personnel on-site or otherwise managed remotely.

Designed, engineered and assembled entirely in WA, the system combines custom-built hardware, proprietary software and pellet-based plastic feedstock – either new or recycled – to create a complete manufacturing setup.

Capable of 3D printing parts up to 10 metres in length, the system can produce everything from seals and gaskets to concrete formwork, architectural sculptures, boat hulls and furniture.

Integrated machining capabilities mean parts can be printed and finished in a single setup, reducing waste, speeding up turnaround times and lowering costs.

“This technology will transform how large industrial components are made. For example, moulds used in boat building that typically take up to six months can now be produced in as little as three days,” said Josh.

“Companies can go from idea to full-scale production without waiting on tooling or overseas parts. We’re offering a smarter alternative, allowing companies to design, test and print within days, then scale when they’re ready.”

Turning Plastic Waste into High-Value Products

Josh said the idea for Hyperion started with a simple question: “What if we could take all the plastic waste out there and turn it into something new and big – like a boat?”

That idea became the foundation for the company’s innovative platform.

Unlike traditional 3D printers, Hyperion’s platform uses Large Format Additive Manufacturing (LFAM) with Fused Granular Fabrication (FGF) to build large scale parts layer by layer.

The printing material used is thermoplastic pellets, which can be recycled from waste streams like containers, PET bottles and even decommissioned subsea infrastructure.

Industry Impact

In just 3 years of operation, Hyperion has:

- 3D printed Australia’s first boat hull, a 3-metre vessel completed in 36 hours

- Built the country’s largest 3D printed structure – a large-scale public artwork at Kalgoorlie TAFE

- Installed a robotic 3D print system for design students at Griffith University

- Delivered projects for marine, oil and gas, construction, education and defence applications

- Expanded into a new, larger facility in Henderson to position for support of marine, defence and subsea businesses within the Australian Marine Complex

In addition to Government funding, Hyperion is also backed by Perth businessman David Budge, co-founder of 3D metal printing success story Aurora Labs Ltd. David was one of Hyperion’s founding investors and now serves as its Chief Technology Officer.

“David’s shift from metals to plastics reflects the opportunity we see in large-format, recycled polymer-based manufacturing faster, cost effective and circular by design,” said Josh.

The federal grant will accelerate the rollout of Hyperion’s Manufacturing-as-a-Service (MaaS) model, allowing businesses to lease and operate the mobile system on their own sites, with options for in-house training or remote operation.

“We’ve built a full-stack solution – hardware, software and materials – all developed here in WA. Our goal is to make high-quality, large-scale production accessible for any company, anywhere, without the overheads of traditional manufacturing,” said Josh.