Horizons broadened

The Horizon Group opened its doors for the first Open House event since 2016, hosting a group of international marine media, dealers and owners at their headquarters in Kaohsiung, Taiwan.

The 2024 Horizon Open House, 5 to 7 March was the company’s first in five years, and the event hosts and visitors were ecstatic to resume the relationship.

Having flown from the US, Europe, Australia and New Zealand to Kaohsiung in the southwest of Taiwan, guests were treated to Horizon’s typically warm hospitality and accommodated at the lavish Grand Hilai Hotel overlooking and within walking distance of Kaohsiung Harbour.

After a rest and adjustment to local time, the first day’s activities commenced with a visit to the undulating landmark, Horizon City Marina, where five brand-new Horizon superyachts awaited inspection. The media group split up and went aboard each model in the line-up: FD80 hull #12, bound for Australia, FD80 hull #14 headed to the US, FD90 hull #30 destined for an Australian owner, and V77 hull#10, both going to the US.

On board the palatial Horizon FD90, Horizon co-founder and Group CEO, John Lu, son and Marketing Director, Joey Lu, Austin Lin, President of Vision Shipyard – part of the Horizon Group – and esteemed Dutch yacht designer responsible for the design of Horizon’s FD Series, Cor D. Rover discussed the diverse features and innovations present in each vessel before opening the session to questions from the media.

Joey Lu commenced his presentation by introducing the Horizon Group and its five companies: Horizon Shipyard, Atech Composites, Vision Shipyard, Premier Shipyard and Horizon City Marina, a centrally located marina with 40 berths for vessels up to 60-metres.

Founded in 2000 and the largest of its kind in Asia, Atech specialises in Fiber Reinforcement (FRP) components, supplying the hull, decks and superstructure of every Horizon yacht. Atech also supplies to a diverse range of clients across marine, aviation, national defence, transportation and infrastructure.

Some examples of its products include the end cab and interior panels for light rail trains in New Taipei City, and nacelle and spinner covers for several offshore wind turbines. Atech proudly manufactured the arch for one of Kaohsiung’s landmarks, the Great Harbor Bridge which spans the recently-developed harbour foreshore.

Horizon Yachts, the world’s ninth largest boat builder, employs over 900 people and builds motor yachts from 80 to 150-feet.

“We specialise in semi-custom construction with a short turnaround of just one year, which is important for customers because they don’t want to wait, and they are becoming less patient,” stated John Lu.

In the past 36 years, Horizon has built 910 yachts spanning eight yacht series. One third of their owners are repeat customers. “Some upsize, some buy the same model with new technology and features on board, some are downsizing – it depends on their stage of life,” John added.

The US remains the largest market for Horizon motor yachts, followed by Australia, Europe and the Asia.

The highest selling Horizon line is the FD Series, which since 2016 has sold 75 boats, 29 of them FD90s.

Designed by Dutch design firm, Cor D. Rover, the FD or “Fast Displacement” series is positioned as offering “a blend of modern flair with functional living and entertaining spaces”.

“The FD series is based on a proven hull, offering owners customisation in layout and interiors,” explained John Lu.

“And while every single one is different, in most cases, 90 percent we have done before and 10 percent is unique.

“We go out of our way to meet customers’ wishes,” he continued. “We’ve even done a 1:1 prototype for an owner – which is not normal – so they could see their vision and how it would work.”

He cited examples such as the FD80 with helipad on deck, and the FD92 “Crowned Eagle”, the brand’s first tri-deck design which featured both an interior pilothouse and an open flybridge – a custom configuration requested by the owners.

“This added another layer of difficulty, but we rose to the challenge. It may be a special build that requires extra engineering and a modified hull, but we try not to say no. We had another 100- foot that had to accommodate a chopper, sub, jetskis, tender, all the toys and big cranes. We can make it work. Our customers come to us with ideas, and Horizon delivers. An FD80 with a small chopper – Let’s try!”

For that reason, Horizon employs a team of 50 naval architects and engineers, “All from the top schools, and many artisans”, Lu asserted.

On display during the 2024 Horizon Open House were the models FD80, FD90, and the V77 with its unique fishing transom – an hydraulic fold-down cockpit transom with large teak deck that can easily transform into a leisure space.

For the Vision Shipyard, which specialises in vessels 50 to 80-feet, the next major project on the drawing board is the new Lexus Yacht, announced at the Horizon Gala Dinner by Mr Go Hayashi, Toyota Marine Business Department New Business Administration Division General Manager.

The Lexus LY 680 is a revision of the LY 650, which made its first foray onto the US market in 2019 and was designed in collaboration with Italian yacht design studio Nuvolari Lenard.

Under the direction of Vision Shipyard President, Austin Lin, the Lexus LY 680 is expected to launch in Japan in 2025.

“This project has been in development for over a year,” said Lin. “Something like this takes a lot of brains working together to get it right.”

In response to journalists’ questions about the impact of the pandemic on yacht production and the Horizon workforce, John Lu explained, “When it first struck in March 2020, we thought it would be the end of the world, and for a while, production did come to a halt.

“But then six months in, it took off again in bigger numbers than ever, with a 10 to 20 percent increase. Even during Covid, we managed to deliver boats.

“We also took advantage of that time to make extensive additions to our factory, including a new plant, sheds and offices, and the upgrade to a new 5-axis CNC machine. This machine is so accurate, we had to get government approval. We are now able to make 3D printing models for clients.

“As a result of the pandemic, production costs and shipping increased, and while they have now reduced somewhat, inflation is impacting pricing and issues with the supply chain can cause delays, so we make sure to keep stock of engines and other components in case.”

During the group discussion, questions ranged from the technical and model-specific to geo-political, particularly from US and Australian media concerning the constant mainstream media fascination with China’s intent and its supposed claim on Taiwan.

A very candid John Lu informed the group, “The small island of Taiwan has the population of Australia – 27 million.

“We have lived with this for 70 years. We keep on living and working and creating. Overseas investment in Taiwan is at a record high. We understand that some prospective owners might be nervous, but we have strategies in place and solutions.”

Revealing plans for expansion at the Premier Shipyard, John Lu apprised the media and guests of Horizon Group’s intention add a refit arm to its business, specialising in megayachts, 30-metres and above.

Located on the waterfront with direct access to the South China Sea, Premier’s 24,000-square-metre facility can accommodate six yachts of 120-feet (40-metres) undercover. The yard also owns an automatic float on/off launch barge with a 500-tonne lifting capacity for yachts of 60-metres. This makes Premier the ideal set off point for sea trials, commissioning, and loading yachts for export.

“Taiwan is the mid-way destination for megayachts cruising the world, around Japan and South-East Asia. Premier Shipyard will soon boost its facilities with a 1,000 Tonne shiplift to specialise in megayacht refit. It’s a huge gamble, but I trust my judgement.”

For Lu, boat building is entirely about delivering what clients want, without losing sight of risk.

He hailed one example as, “A long-time client wanted a 50-metre catamaran, but it was not within my comfort zone, so I had to say no.”

“We are client focused, and we are one step ahead, but we will not go beyond the risks I’m prepared to take.”

At the conclusion of the first day of the 2024 Horizon Open House, John Lu thanked visiting media, owners and guests, saying “We know it’s hard to get to Taiwan, and we appreciate your willingness to join us here to understand Horizon.

“Our brand values continue to be: reliability in our company, product and people. Horizon owners have a passion for the sea. They are not flashy. They enjoy their boat as a house on water. They are family oriented, adventurous, real boaties.”

Day 2 of the Horizon Open House started with a tour of Kaohsiung City. Aboard two open-top tourist buses, the group was ferried around the sights of this industrial hub which has undergone a remarkable transformation over the past four years, largely under the direction of the Mayor Chen Chi-Mai who has held the position since 2020.

Sights included the Pier 2 Art Centre, Great Harbour Bridge and Dagou Harbour with its revived dining and entertainment precinct along Shaochuan Street. Taiwanese hospitality and delicacies were demonstrated at a banquet lunch at “Old New Taiwanese Cuisine” restaurant. Dish after dish was served, washed down with refreshing pineapple juice or the local beer.

Then it was back to the Hotel for a rest and refresh before returning to Horizon City Marina and the much-anticipated Yacht Hop and Horizon Open House Party.

As the sun set, illuminating the Horizon vessels on show, guests mingled with Horizon management, and helped themselves to the bountiful buffet, with live music, motor yachts and the harbour the perfect backdrop.

The third and final day consisted of a tour of the Atech and Horizon factories.

“We invest heavily in technology throughout the entire design and build process,” explained Weston Lu, John’s second son.

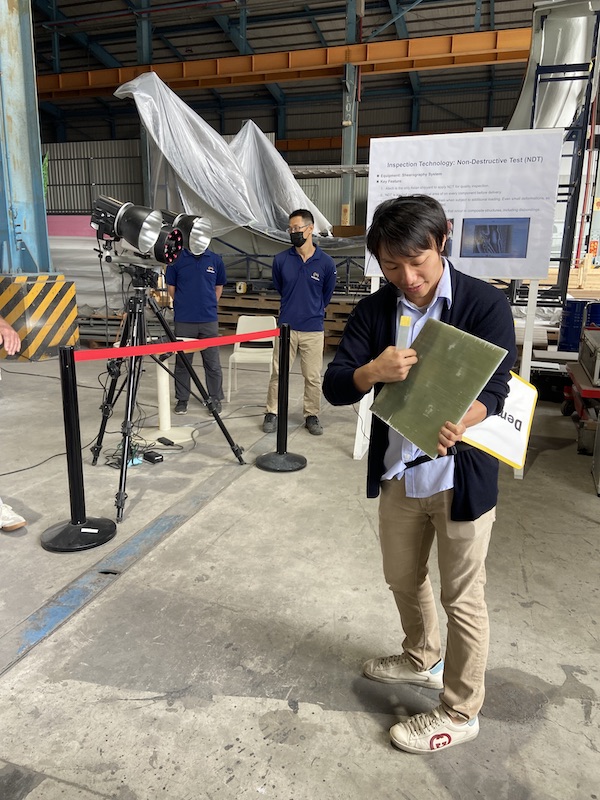

Drawing on its background in aerospace technology, Atech undertakes Profile Measurement and Non-Destructive Testing into its build processes to ensure the precise dimensions of each vessel.

Using high-speed laser scanning, Reality Capture is used to capture the actual dimensions of each piece required for a vessel. Subsequently, materials are cut using “kit technology” where each piece is numbered, vastly improving efficiency and optimising the FRP manufacturing process by less waste and fewer defects.

Reality Capture is applied before production to check the mold dimensions, as well as during production to ensure structural positioning, and then post-production to ensure alignment with technical drawings.

At the Horizon production facility, the group inspected the various models lined up in the new sheds outside, ready for testing, and those in production, including RP120, FD90 and FD80, assigned flags to indicate their delivery destinations.

Of particular interest were the largest 5-axis CNC machine in Taiwan, 3D printer, massive test tanks used to put vessels through their paces, testing roll and stability in rough conditions, and intense water pressure to check for leaks, and their patented 6D infusion process which the Horizon team demonstrated.

6D infusion ensures even resin distribution, making hulls eight percent lighter than hull shells that require secondary bonding, and 40 percent stronger than hulls produced by hand lay-up process.

According to Weston Lu, in 2019 the Atech R&D team set the world record for a single-shot hull infusion on a 140-foot hull, using the vacuum infusion technology and their proprietary 3D resin flow. The infusion process facilitates the flow of resin into fibre interstices and core material grooves through pressure variation. As hull design and lengths have changed, so have Horizon’s techniques.

In 2020, Atech refined its 3D infusion capabilities by introducing and patenting 6D vacuum infusion technology in which the 3D macro structures and 3D micro structures and infused in one shot to form a one-piece hull.

This improved technology ensures consistency throughout all structural components, creates hulls that are as light and as strong as possible, and reduces the emission of Volatile Organic Compounds (VOCs) by nearly 80 percent.

Quality control is equally high-tech, using laser and thermal techniques. Active infrared thermography and laser shearography methods are part of the non-destructive testing (NDT) used to reveal sub-surface defects.

The final evening was spent as a combined group – owners, dealers, suppliers and media – enjoying pizza and beer at a waterfront tavern. After thanking guests profusely for their faith in the brand and their willingness to travel to Taiwan from all parts of the globe, John Lu and his wife Alice, declared the 2024 Horizon Open House a tremendous success, and the singing, dancing and shared stories unfolded well into the night.

From Perth, the owners of the Horizon E84 “Destiny”, made the trip to Taiwan with their skipper. This was their first time visiting the Horizon factory and they were “absolutely blown away” with the level of technology and commitment to quality control that they experienced.

“Horizon boats are world-class,” they said. “Speaking directly with John Lu, it’s easy to see how dedicated they are to bringing owners’ dreams to life.

“In 2021, we spent three months around Broome and the Kimberleys with four groups of friends who would fly up; fishing, bushwalking, swimming in rockpools, waterfalls, the incredible scenery. While we were in Geraldton, there was a tropical cyclone – 84 knots, and huge swells. Our boat was in the eye of the cyclone and came out with no damage – testament to its design and construction.”

Another Perth-based couple who use their E75 “GT” on the east coast, said they were amazed at the level of customisation Horizon offers. “It was amazing to see the boats in build at the factory and to understand the investment behind the composites and testing.”

PC52 “Aurora” owners from Harvey Bay were equally impressed with Horizon operations and the insight gained during the three-day Open House. They praised the Horizon Yacht Australia team – Mark, Erica, Tony, and Jessica – for their expertise and warm welcome at every Horizon event. “It is like being part of a family. We all share a love of boating.”