Article by Hans Buitelaar, Metstrade

Additive Manufacturing, also known as 3D printing, is set to change the production process of boat propellers. Answering to developments in the marine industry like electrification of propulsion and hydrofoiling, this technique allows for specialised propellers to be produced at low cost and reduced use of material that can be optimised to meet the operational demands of any specific boat.

The complexity of propeller design

Creating the exact right propeller for a ship is a complicated process. A lot of variables have to be taken into account to design a propeller that will perform under all of the different situations in which a boat will sail.

Matching propellers to vessel type and conditions

The size of the boat is to be considered, it’s weight, the desired speed and the expected conditions in which a boat will be used. It is not so hard to understand that the size and shape of propeller blades of a small planing boat that is racing on a lake need to be quite different than the propeller blades for a sailing yacht that uses the engine to get from open sea with big waves safely into a harbour at slow speed.

There are differences in the engines: at which rotation speed will they deliver the best performance? Will the propeller deliver it’s best propulsion power at that same speed?

And then there are so many variations in the propeller itself: the diameter and the number of the blades. Will the blades be overlapping or leave a lot of space in between? How much pitch do the propeller blades have? Or in the case of larger yachts, will the choice be made to install controllable pitch propellers?

In general, one can say that narrow shaped propeller blades with a thick cut-through profile will deliver a lot of pulling force at slower speeds, while wide shaped thin blades a better suited for high speed sailing.

Praise the propeller

Design of well performing ship and yacht propellers has evolved to be a field of science in itself. It the Maritime Research Centre MARIN in the Netherlands, the scientists have made a collection of the types and designs of propellers that they have done tests with.

Even though these are scale models, the rows of screws hanging on the wall span the whole length of the building along the 224 metre test basin multiple times. There are thousands of designs. The number of designs is ever increasing.

All this optimising of the shapes of these underwater screws aims to get the best possible performance out of the engine power that the boat delivers. Overall, the ship propeller is a very good concept. Boat propellers can be praised as the most efficient mechanical device to transfer engine power into thrust in the water.

Strong alloys for marine propellers

Under water, propellers are exposed to powers causing wear and tear: the torque from the shaft that comes from the engine, the resistance of the water and the turbulence of the water surrounding the blades.

As the boat needs to sail at speed, the blade tips rotate at quite high speed through the water and cause vacuum bells. This phenomenon is called cavitation. Cavitation causes detoriation of screws and corrosion. The design of propellers needs to consider this.

To withstand al of these forces, the materials of boat propellers need to be tough. The propellers for small electric trolling motors on dinghies and fishing boats can be made in composites, but bigger and faster boats require tougher materials.

Most propeller manufacturers use alloys. For lighter outboard engines, aluminium can be sufficient. A lot of larger and fast sailing boats use stainless steel props. For its good capabilities being repellent to marine fouling, withstanding large forces and enduring the saline environment in sea water, bronze is the more traditional material favoured by mariners for use in screws. Larger boats may use refined metal alloys combining like Bronze-Aluminium-Nickel or Copper-Nickel.

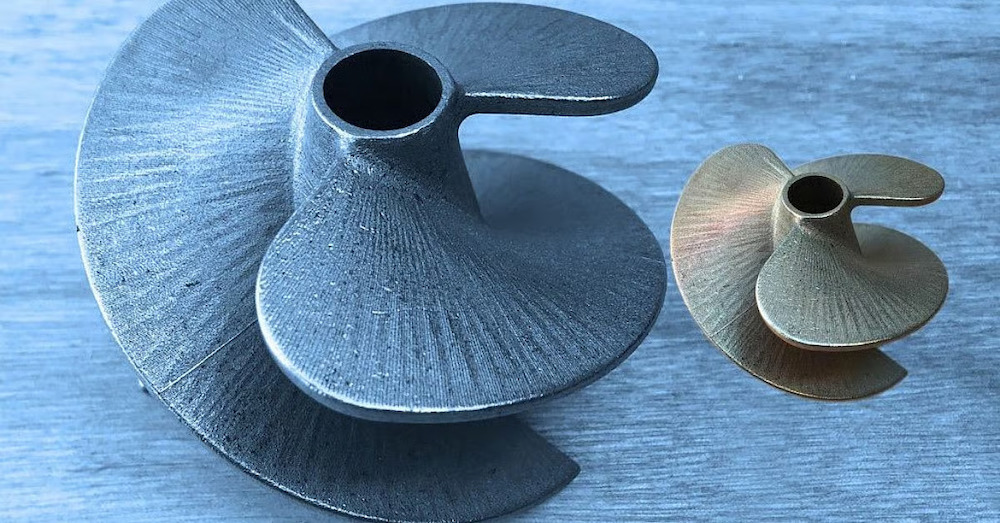

Shaped in sand, traditional propeller casting

The complicated shapes of boat propellers are usually created by pouring molten metal into a mould. Traditionally, the moulds would be made in sand. This allows for flexible shaping.

After curing, the resulting boat screw needs a lot of treatment to refine the shape of the blades and smoothen the surface. Automation in production processes led to surface treatment using robot arms that could smoothen the surface using laser beams or mechanical milling.

Melting metal, the first 3D printed prop

In 2017, Dutch maritime start-up RAMLAB produced the first ship propeller made with 3D printing to receive approval by maritime certification institute Bureau Veritas. This marked a breaktrough in both additive manufacturing as in propeller production.

Because 3D printing is a process of adding a new layer of material over the previous, the kind of materials that can be produced is limited. After the first applications with soft plastics with a low melting temperature, the process of additive manufacturing has evolved towards processing metal alloys with the use of a special nozzle that can heat the metal alloy to the temperatures need to achieve a good bonding with the former layer to create a structure strong enough for a certified seagoing vessel’s prop.

Shaping wire

The procedure used by RAMLAB is called Wire Arc Additive Manufacturing. A robot arm is fed with a wire of a Nickel-Aluminium-Bronze alloy. The robot arm moves around the structure it is creating, pouring the molten alloy from the wire layer over layer.

A specially developed heating nozzle deposits the layers of molten metal in the correct spots, controlled by a computer programme to secure that the correct shape of the propeller will be constructed.

Metal powder printing

Today, Chinese company Metal3DP Technology (with offices in Korea and Singapore) is producing boat propellers with a different technique: 3D printing using metal powder. They call it MAM: metal additive manufacturing.

This company offers a lot of different powders to create 3D printed structures in a lot of different alloys, ranging from the softer metals like aluminium to extremely low weight, high strength materials like titanium.

Additive manufacturing gives naval architects design freedom. It liberates propeller design from the constraints of traditional casting moulds and machining access.

Optimised propellers can be tailored to specific vessel requirements. Creating optimised propellers brings a lot of benefits: improved fuel efficiency, reduced cavitation and noise and the potential for lighter, integrated propulsion components.

Accelerating innovation in marine propulsion

Recent developments call for optimised screw designs. Electric motors deliver other power characteristics than internal combustion engines.

Foiling boats need the power to speed up quickly to get up on their foils, but once on their foils maintain their speed at a lot less drag.

The potential of quickly producing propellers and being able to easily make subtle changes in design, will allow for further innovation in ship propulsion.